Company News

Simtek EMS – Expands UK manufacturing facility

20th March, 2011

As a result of this, a new Stencil Printer and Placement system from Blakell Europlacer have been ordered to augment SIMTEK’s existing production capabilities.

“We have been involved in manufacturing electronic assemblies for over 14 years, and during that time we have seen many changes to the UK market. In recent times, many manufacturers have sent their products to the Far East in an short sighted attempt to reduce costs” says Richard, “however as long as two years ago, we started to see certain products returning to be made in the UK, mainly due to the inflexibility and lead time constraints that come with off shore manufacturing”.

Now that customers are very keenly looking at the “total cost” of a products life cycle they are coming to realise that support, component obsolescence and protection of intellectual property are all very costly when controlled at arm’s length.

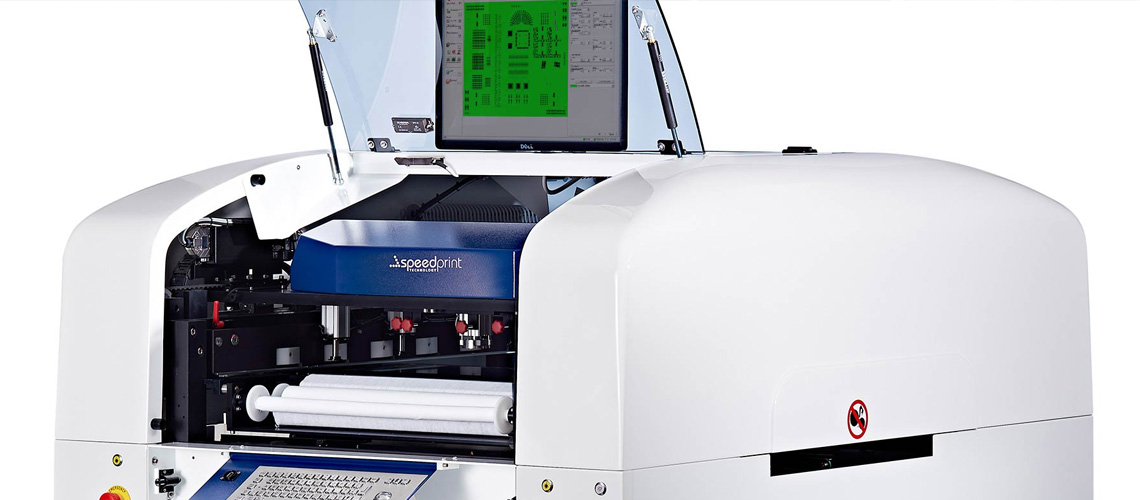

he addition of a Speedprint SP700 and a Europlacer iineo I machine help to address the requirements of flexibility, technological advances and increase in capacity.

With the ability to handle stencil sizes up to 29″ and the capability to print down to device sizes of 01005 (0.4mm x 0.2mm) the Speedprint SP700 adds significant benefits. The simple graphical interface allows for ease of setup and changeover and is key in being able to maintain flexibility, while linear encoded drives with 1 micron resolution result in extremely accurate print positioning.

“We were amazed by the simplicity of the design of the Speed print” commented Lee Boulton, SIMTEK’s Operations Director, “We attended a Europlacer technology day during last year, and were very impressed by the way the Speedprint SP700 has been designed and assembled. When we opened the lid on the machine, we were struck by how little there is both mechanically and electronically and therefore how little there is to go wrong! We saw 01005 pads being printed repeatedly and accurately and decided there and then that Speedprint was the right decision for us going forward”.

To complement the printer, SIMTEK EMS also invested in the award winning iineo I system.

“We already have Europlacer Finesse machines, and associated feeders, so the decision to buy another system was made a little easier for us. However even if we had started with a blank piece of paper, the iineo would certainly have been in our reckoning as its flexibility and technical capabilities perfectly match our requirements as contract electronics manufacturer” stated Richard.

The Europlacer iineo system can handle devices from 01005 up to 50 x 50mm in size without the need for additional cameras to be fitted. It has capacity for 264 x 8mm feeders and can also hold up to 10 x full sized JEDEC trays internally without a reduction in the maximum PCB size 700 x 460mm.

Richard commented “Being able to use our existing Europlacer feeders, and with the new operating software looking almost identical to our current machines, we are delighted to have chosen Europlacer as our partner for our current expansion – we are looking forward to more customers sending their manufacturing to the Far East… of the UK!”